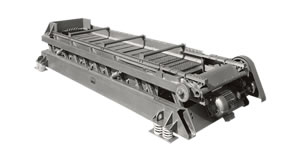

F Screen

The F-Screen is the most versatile and best known of the Symons Screens. It was engineered for accuracy and capacity in the sizing of aggregates and is widely used in rock and gravel plants as a finishing screen. The adaptability of the F Screen makes it an ideal selection for special screening conditions, so it is widely used in other industrial operations.

Asphalt

Aggregate

Rock

Gravel

Sand

Coal

Ore

Designed for sizing accuracy and capacity, with its low headroom, easy access vibrator unit and unique base isolation system, the F Screen is perfect for asphalt plant operation, finished aggregate screening and rescreening. Available in a variety of sizes.

Consisting of four major parts:

1 - Screening Deck is of rigid box construction carrying surfaces on removable steel frames.

2 - Balance Deck consists of heavy steel bars on each side of the screening deck. The feed box is mounted on these heavy bars and becomes part of the balance deck. A built-in vibrating feed box with distributor spreads material over the width of the screen at the head end, utilizing every inch of the screen surface.

3 - Steel Channel Base is attached to the screening and balance deck by support springs. These springs are made of thin alloy strips clamped together and set at an angle of 60 degrees to horizontal.

4 - Shaft Assembly is bolted solidly to the balance deck and flexibility connected to the screening deck by four drive springs, which translates the rotary eccentric action to the shaft to a positive reciprocating action of the screening deck, without use of reciprocating bearings. Very little vibration is transmitted to the base.

Economy

Efficient for wet screening and washing, since the water is removed quickly and does not run down the screen as in inclined types.

Capacity

Quickly stratifies the pad of material, placing the fines on the bottom next to the cloth for rapid removal.

Positive throw assures that the screen will not over-throw under light loads or kill out under heavy loads.

Long Life

The 30 degree conveying action carries material over the screen. When cloth and material are in contact they move in the same direction and speed, so there is little abrasion.

Accurate Sizing

Sits level so the full openings of the screen surface are utilized. Flow of material is positively controlled by the mechanical action of the screen eliminating bouncing and cascading of material.

Low Headroom

Requires much less headroom allowing it to be enclosed. Adaptability for mounting over's bins and absence of base vibration makes this screen ideal for paving plant use.

Motor, V-belt drive and shaft assembly are outside the housing away from heat and dust.all parts are readily accessible.

| A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| Screen Size | No. Decks | Weight lbs. | Feed in T.P.H. | Cloth Width | H.P. | Deck Length | Feed Box | Overall Height | Discharge Width | Shipping Width | O.S. Base | Base Length | Base Width |

| 36 x 8 | 2, 2.5 | 7300 | 75 | 36 | 5 | 8-0 | 36 | 42.5 | 28 | 66 1/4 | 53 1/4 | 11-4 1/4 | 68 1/2 |

| 36 x 10 | 2, 2.5 | 7900 | 95 | 36 | 5 | 10-0" | 36 | 42.5 | 28 | 66 1-4 | 6-1/2 | 13-4 1/4 | 81 1/4 |

| 48 x 8 | 2, 2.5 | 8600 | 100 | 48 | 5 | 8-0 | 48 | 42.5 | 40 | 79 1/4 | 6-1/4 | 11-4 1/4 | 81 1/4 |

| 48 x 10 | 2, 2.5 | 9800 | 125 | 48 | 7 1/2 | 10-0 | 48 | 42.5 | 40 | 79 1/4 | 6-1/4 | 13-4 1/4 | 81 1/4 |

| 48 x 12 | 3 | 14500 | 150 | 48 | 7 1/2 | 12-0 | 48 | 42.5 | 40 | 81 1/4 | 6-1/4 | 15-4 1/4 | 83 1/4 |

| 48 x 14 | 3.5 | 16000 | 175 | 48 | 10 | 14-0 | 48 | 42.5 | 40 | 88 | 73 | 17-9 3/4 | 90 |

| 48 x 16 | 3, 3.5 | 18000 | 200 | 48 | 15 | 16-0 | 48 | 42.5 | 40 | 88 | 73 | 19-4 3/4 | 90 |